Graco Diaphragm Pump HUSKY 2150 Model DF3525

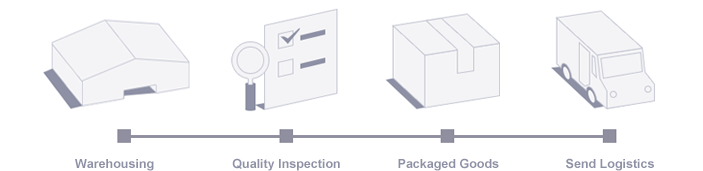

Packing and shipping

|

Packaging Regulation : |

Wooden box |

|

Delivery time : |

7~14 days(About) |

|

Conditions : |

New and Genuine |

How do you order?

A&S makes ordering GET Parts easy. Simply send a mail to Us. Instead of searching online and guessing which parts you need, our team will make sure you get the correct parts. We process and deliver your order fast, and always at a competitive price. Enjoy 5-star service!

1.IDENTIFY

Determine the parts you need. To ensure the correct parts are quoted, it's best to have the machine make and model, along with part numbers and photos of the nameplate if possible. Our team of professionals are here to help ensure you get the correct parts that fit and work the first time. Our sales team can also survey and help identify the parts you may need. Please email us to get started!

2.ORDER

Our professional internal sales teams and strong supply chain system will assist you to identify the right parts, and can recommend the most cost-effective solution for you. Our team of professionals will process your order, and ensure your order is correct the first time. With over 15 years in the business, we remove the guesswork and always deliver.

3.DELIVER

We'll ship or deliver your products as required, to your nominated location. If you're also located elsewhere, we'll identify the best shipping options for both price and delivery time. Email us now!

HUSKY 2150 Model DF3525-A0217092

Husky 2150 Aira€“Operated Diaphragm Pumps

See Models on page 2 for a list of pump models and descriptions.

120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure 120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

Patent No.

CN ZL94102643.4 FR 9408894

JA 3517270

US 5,368,452

Important Safety Instructions

Read all warnings and instructions in the manual. Save these instructions.

Models

|

Model No. |

Description |

|

*DF3 |

Aluminum Pumps |

|

*DG3 |

Aluminum Pumps, Remote |

|

*DFH |

Aluminum Extended Pump |

|

*DGH |

Aluminum Extended Pump, Remote |

|

*DF4 |

Stainless Steel Pumps |

|

*DG4 |

Stainless Steel Pumps, Remote |

|

*DF6 |

Ductile Iron Pumps |

|

*DG6 |

Ductile Iron Pumps, Remote |

|

*DFC |

Aluminum BSPT Pumps |

|

*DGC |

Aluminum BSPT Pumps, Remote |

|

*DFD |

Stainless Steel BSPT Pumps |

|

*DGD |

Stainless Steel BSPT Pumps, Remote |

|

*DFF |

Ductile Iron BSPT Pumps |

|

*DGF |

Ductile Iron BSPT Pumps, Remote |

|

*DFG |

Aluminum BSPT Extended Pump |

|

*DGG |

Aluminum BSPT Extended Pump, Remote |

|

*DV4 |

Stainless Steel Plus Pumps |

|

*DVD |

Stainless Steel BSPT Plus Pumps |

|

232503 |

Privatea€“Label Aluminum 2150 Pump (See page 22.) |

|

24B782 |

Aluminum Pump with overmolded diaphragms |

|

24B783 |

Stainless Steel Plus Pump with overmolded diaphragms |

|

24B801 |

Stainless Steel Pump with overmolded diaphragms |

*NOTE: Refer to the Pump Matrix on page 22 to determine the Model No. of your pump.

NOTE: Plus Models include stainless steel center sections.

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Any misuse of the equipment or accessories, such as overpressurizing, modifying parts, using incompatible chemicals and fluids, or using worn or damaged parts, can cause them to rupture and result in splashing in the eyes or on the skin, other serious injury, or fire, explosion or property dam- age.

a€¢This equipment is for professional use only. Observe all warnings. Read and understand all instruction manuals, warning labels, and tags before operating the equipment.

a€¢Never alter or modify any part of this equipment; doing so could cause it to malfunction. Use only genuine Graco parts and accessories.

a€¢Check all equipment regularly and repair or replace worn or damaged parts immediately.

a€¢Never exceed the recommended working pressure or the maximum air inlet pressure stated on your pump or in the Technical Data on page 32.

a€¢Do not exceed the maximum working pressure of the lowest rated component in your system. This equipment has a 120 psi (0.8 MPa, 8 bar) maximum working pressure at 120 psi (0.8 MPa, 8 bar) maximum incoming air pressure.

a€¢Be sure that all fluids and solvents used are chemically compatible with the wetted parts shown in the Technical Data on page 32. Always read the manufacturera€?s literature before using fluid or solvent in the pump.

a€¢Never move or lift a pump under pressure. If dropped, the fluid section may rupture. Always follow the Pressure Relief Procedure on page 10 before moving or lifting the pump. The pump is very heavy. If it must be moved, have two people lift the pump by grasping the outlet manifold securely.

HAZARDOUS FLUIDS

Improper handling of hazardous fluids or inhaling toxic vapors can cause extremely serious injury, even death, due to splashing in the eyes, ingestion, or bodily contamination. Observe all the follow- ing precautions when handling known or potentially hazardous fluids.

a€¢Know what fluid you are pumping and its specific hazards. Take precautions to avoid a toxic fluid spill.

a€¢Always wear appropriate clothing and equipment, such as eye protection and breathing appara- tus, to protect yourself.

a€¢Store hazardous fluid in an appropriate, approved container. Dispose of it according to all Local, State and Federal guidelines for hazardous fluids.

a€¢Secure the fluid outlet hose tightly into the receiving container to prevent it from coming loose and improperly draining the fluid.

a€¢Pipe and dispose of the exhaust air safely, away from people, animals, and food handling areas. If the diaphragm fails, the fluid is exhausted along with the air. See Air Exhaust Ventilation on page 9.

FIRE AND EXPLOSION HAZARD

Static electricity is created by the flow of fluid through the pump and hose. If the equipment is not properly grounded, sparking may occur. Sparks can ignite fumes from solvents and the fluid being pumped, dust particles and other flammable substances, whether you are pumping indoors or out- doors, and can cause a fire or explosion and serious injury and property damage.

a€¢To reduce the risk of static sparking, ground the pump and all other equipment used or located in the work area. Check your local electrical code for detailed grounding instructions for your area and type of equipment. Refer to Grounding on page 5.

a€¢If you experience any static sparking or even a slight shock while using this equipment, stop pumping immediately. Check the entire system for proper grounding. Do not use the system again until the problem has been identified and corrected.

a€¢Pipe and dispose of the exhaust air safely, away from all sources of ignition. If the diaphragm fails, the fluid is exhausted along with the air. See Air Exhaust Ventilation on page 9.

a€¢Do not smoke in the work area. Do not operate the equipment near a source of ignition or an open flame, such as a pilot light.

HALOGENATED HYDROCARBON HAZARD

Never use 1,1,1a€“trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in Aluminum Pumps. Such use could result in a serious chemical reaction, with the possibility of explosion, which could cause death, serious injury and/or substantial property damage.

Consult your fluid suppliers to ensure that the fluids used are compatible with aluminum parts.

Installation

General Information

a€¢The Typical Installation shown in Fig. 2 is only a

guide for selecting and installing system compo- nents. Contact your Graco distributor or Graco Technical Assistance (see back page) for assis- tance in planning a system to suit your needs.

a€¢Always use Genuine Graco Parts and Accessories.