SANDPIPER Diaphragm Pump S05B2P1TPNS000

Packing and shipping

|

Packaging Regulation : |

Wooden box |

|

Delivery time : |

7~14 days(About) |

|

Conditions : |

New and Genuine |

How do you order?

A&S makes ordering GET Parts easy. Simply send a mail to Us. Instead of searching online and guessing which parts you need, our team will make sure you get the correct parts. We process and deliver your order fast, and always at a competitive price. Enjoy 5-star service!

1.IDENTIFY

Determine the parts you need. To ensure the correct parts are quoted, it's best to have the machine make and model, along with part numbers and photos of the nameplate if possible. Our team of professionals are here to help ensure you get the correct parts that fit and work the first time. Our sales team can also survey and help identify the parts you may need. Please email us to get started!

2.ORDER

Our professional internal sales teams and strong supply chain system will assist you to identify the right parts, and can recommend the most cost-effective solution for you. Our team of professionals will process your order, and ensure your order is correct the first time. With over 15 years in the business, we remove the guesswork and always deliver.

3.DELIVER

We'll ship or deliver your products as required, to your nominated location. If you're also located elsewhere, we'll identify the best shipping options for both price and delivery time. Email us now!

S05B2P1TPNS000-B1904150208

S15 NON-METALLIC PUMP

TECHNICAL DATA SHEET

SERIES

STANDARD DUTY BALL VALVE PUMPS

Offering the widest range of performance and application capabilities

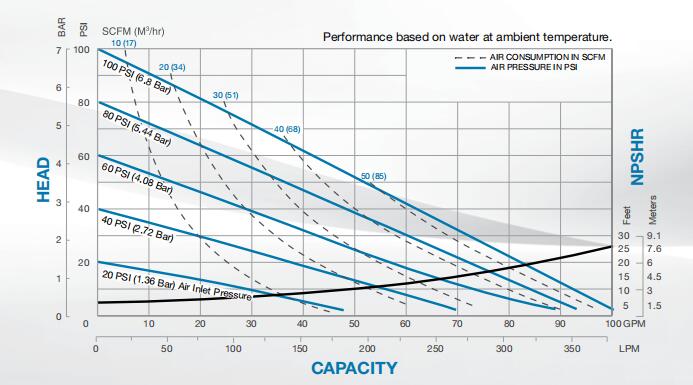

PERFORMANCE

SUCTION / DISCHARGE PORT SIZE

•1 1/2 ANSI Flange or

•PN10 40mm DIN Flange

CAPACITY

•0 to 100 GPM (0 to 378 LPM)

AIR DISTRIBUTION VALVE

•No-lube, no-stall design

SOLIDS-HANDLING

•Up to .47 in. (12mm)

HEADS UP TO

•100 psi or 231 ft. of water (7 bar or 70 meters)

MAXIMUM OPERATING PRESSURE

•100 psi (7 bar)

DISPLACEMENT/STROKE

•.43 Gallon / 1.63 liter

WEIGHTS

•Polypropylene 82 lbs. (37kg)

•PVDF 112 lbs. (51kg)

•Conductive Polypropylene 85 lbs. (38kg)

•Polypropylene Spill Containment 149 lbs. (68kg)

•PVDF Spill Containment 194 lbs. (88kg)

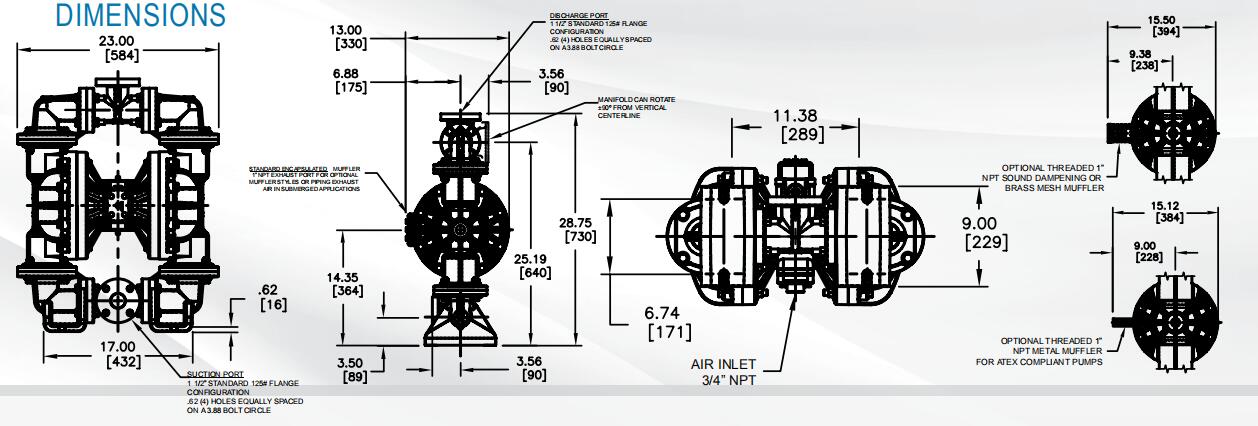

DIMENSIONS

EXPLANATION OF PUMP NOMENCLATURE

Your Model #: S (fill in from pump nameplate)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

Pump Config. |

Pump Size |

Check Valve |

Design Level |

Wetted Material |

Diaphragm/ Check Valve |

Check Valve Seat |

Non-Wetted Material |

Porting Options |

Pump Style |

Pump Options |

Kit Options |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

Model #:S XX X X X X X X X X X XX

PUMP BRAND

S SANDPIPER®

PUMP SIZE

15 1 1/2”

CHECK VALVE TYPE

B Ball

DESIGN LEVEL

3 Design Level

WETTED MATERIAL

K PVDF

P Polypropylene

C Conductive Polypropylene

DIAPHRAGM/CHECK VALVE MATERIALS

1 Santoprene/Santoprene

2 PTFE-Santoprene Backup/PTFE

6 PTFE Pumping, PTFE-Neoprene Backup Driver/PTFE

B Nitrile/Nitrile

C FKM / PTFE

G PTFE-Neoprene Backup/PTFE

M Santoprene/PTFE

N Neoprene/Neoprene

U Urethane/Urethane

Z One-Piece Bonded/PTFE

CHECK VALVE SEAT

K PVDF

P Polypropylene

NON-WETTED MATERIAL OPTIONS

C Carbon Filled Conductive Polypropylene

P 40%Glass Filled Polypropylene

1 40%Glass Filled Polypropylene w/PTFE Coated Hardware

PORTING OPTIONS

A ANSI Flange

D DIN Flange

7 Dual Porting (ANSI)

8 Top Dual Porting (ANSI)

9 Bottom Dual Porting (ANSI)

PUMP STYLE

D with Electronic Leak Detection (110V)

E with Electronic Leak Detection (220V)

M with Mechanical Leak Detection

S Standard

V with Visual Leak Detection

PUMP OPTIONS

0 None

6 Metal Muffler

KIT OPTIONS

00. None

P0. 10.30VDC Pulse Output Kit

P1. Intrinsically-Safe 5.30VDC, 110/120VAC 220/240 VAC Pulse Output Kit

P2. 110/120 or 220/240VAC Pulse Output Kit

E0. Solenoid Kit with 24VDC Coil

E1. Solenoid Kit with 24VDC Explosion-Proof Coil

E2. Solenoid Kit with 24VAC/12VDC Coil

E3. Solenoid Kit with 12VDC Explosion-Proof Coil

E4. Solenoid Kit with 110VAC Coil

E5. Solenoid Kit with 110VAC Explosion-Proof Coil

E6. Solenoid Kit with 220VAC Coil

E7. Solenoid Kit with 220VAC Explosion-Proof Coil

E8. Solenoid Kit with 110VAC, 50 Hz Explosion-Proof Coil

E9. Solenoid Kit with 230VAC, 50 Hz Explosion-Proof Coil

SP. Stroke Indicator Pins

A1. Solenoid Kit with 12 VDC ATEX Compliant Coil

A2. Solenoid Kit with 24 VDC ATEX Compliant Coil

A3. Solenoid Kit with 110/120 VAC 50/60 Hz ATEX Compliant Coil

A4. Solenoid Kit with 220/240 VAC 50/60 Hz ATEX Compliant

MATERIALS

|

Material Profile: CAUTION! Operating temperature limitations are as follows: |

Operating Temperatures: |

|

|

Max. |

Min. |

|

|

CONDUCTIVE ACETAL: Tough, impact resistant, ductile. Good abrasion resistance and low friction surface. Generally inert, with good chemical resistance except for strong acids and oxidizing agents. |

190°F 88°C |

-20°F -29°C |

|

EPDM: Shows very good water and chemical resistance. Has poor resistance to oils and solvents, but is fair in ketones and alcohols. |

280°F 138°C |

-40°F -40°C |

|

FKM (FLUOROCARBON): Shows good resistance to a wide range of oils and solvents; especially all aliphatic, aromatic and halogenated hydrocarbons, acids, animal and vegetable oils. Hot water or hot aqueous solutions (over 70°F(21°C)) will attack FKM. |

350°F 177°C |

-40°F -40°C |

|

HYTREL®: Good on acids, bases, amines and glycols at room temperatures only. |

220°F 104°C |

-20°F -29°C |

|

NEOPRENE: All purpose. Resistance to vegetable oils. Gener- ally not affected by moderate chemicals, fats, greases and many oils and solvents. Generally attacked by strong oxidizing acids, ketones, esters and nitro hydrocarbons and chlorinated aromatic hydrocarbons. |

200°F 93°C |

-10°F -23°C |

|

NITRILE: General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should not be used with highly polar solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons. |

190°F 88°C |

-10°F -23°C |

|

NYLON: 6/6 High strength and toughness over a wide tem- perature range. Moderate to good resistance to fuels, oils and chemicals. |

180°F 82°C |

32°F 0°C |

|

POLYPROPYLENE: A thermoplastic polymer. Moderate tensile and flex strength. Resists stong acids and alkali. Attacked by chlorine, fuming nitric acid and other strong oxidizing agents. |

180°F 82°C |

32°F 0°C |

|

PVDF: (Polyvinylidene Fluoride) A durable fluoroplastic with excellent chemical resistance. Excellent for UV applications. High tensile strength and impact resistance. |

250°F 121°C |

0°F -18°C |

|

SANTOPRENE®: Injection molded thermoplastic elastomer with no fabric layer. Long mechanical flex life. Excellent abrasion resistance. |

275°F 135°C |

-40°F -40°C |

|

UHMW PE: A thermoplastic that is highly resistant to a broad range of chemicals. Exhibits outstanding abrasion and impact resistance, along with environmental stress-cracking resistance. |

180°F 82°C |

-35°F -37°C |

|

URETHANE: Shows good resistance to abrasives. Has poor resistance to most solvents and oils. |

150°F 66°C |

32°F 0°C |

|

VIRGIN PTFE: (PFA/TFE) Chemically inert, virtually impervious. Very few chemicals are known to chemically react with PTFE; molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures. |

220°F 104°C |

-35°F -37°C |

|

Maximum and Minimum Temperatures are the limits for which these materials can be operated. Temperatures coupled with pressure affect the longevity of diaphragm pump components. Maximum life should not be expected at the extreme limits of the temperature ranges. |

||

|

Metals: |

||

|

ALLOY C: Equal to ASTM494 CW-12M-1 specification for nickel and nickel alloy. |

||

|

STAINLESS STEEL: Equal to or exceeding ASTM specification A743 CF-8M for corro- sion resistant iron chromium, iron chromium nickel and nickel based alloy castings for general applications. Commonly referred to as 316 Stainless Steel in the pump industry. |

||